ROPE ACCESS VS BMU

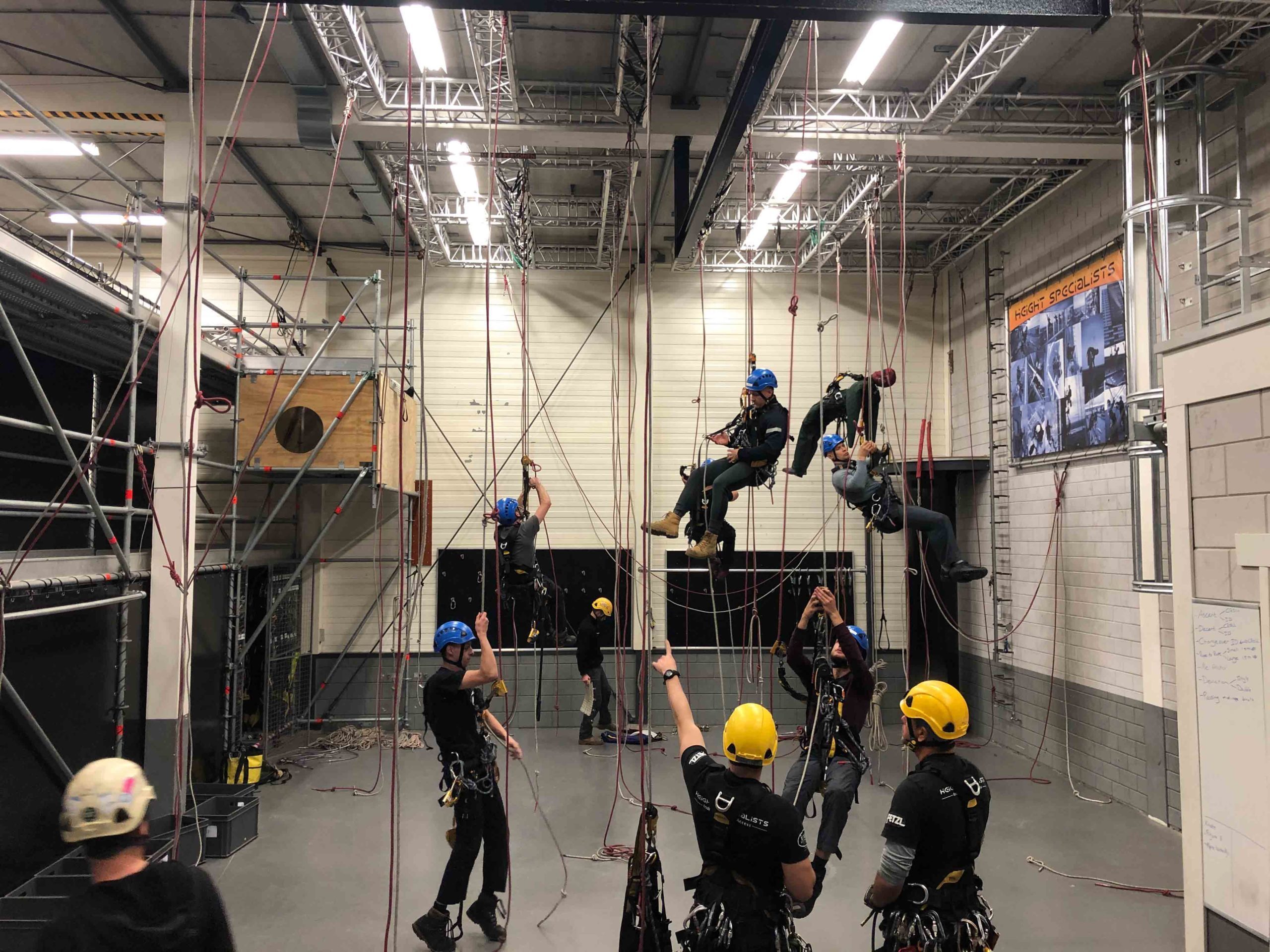

RA ERGONOMICS

The comfort condition for operative is optimal because the operator is seated. The harness must satisfy specific ergonomic standards. Operators are positioned in front of the work area at an optimal distance from the facade.

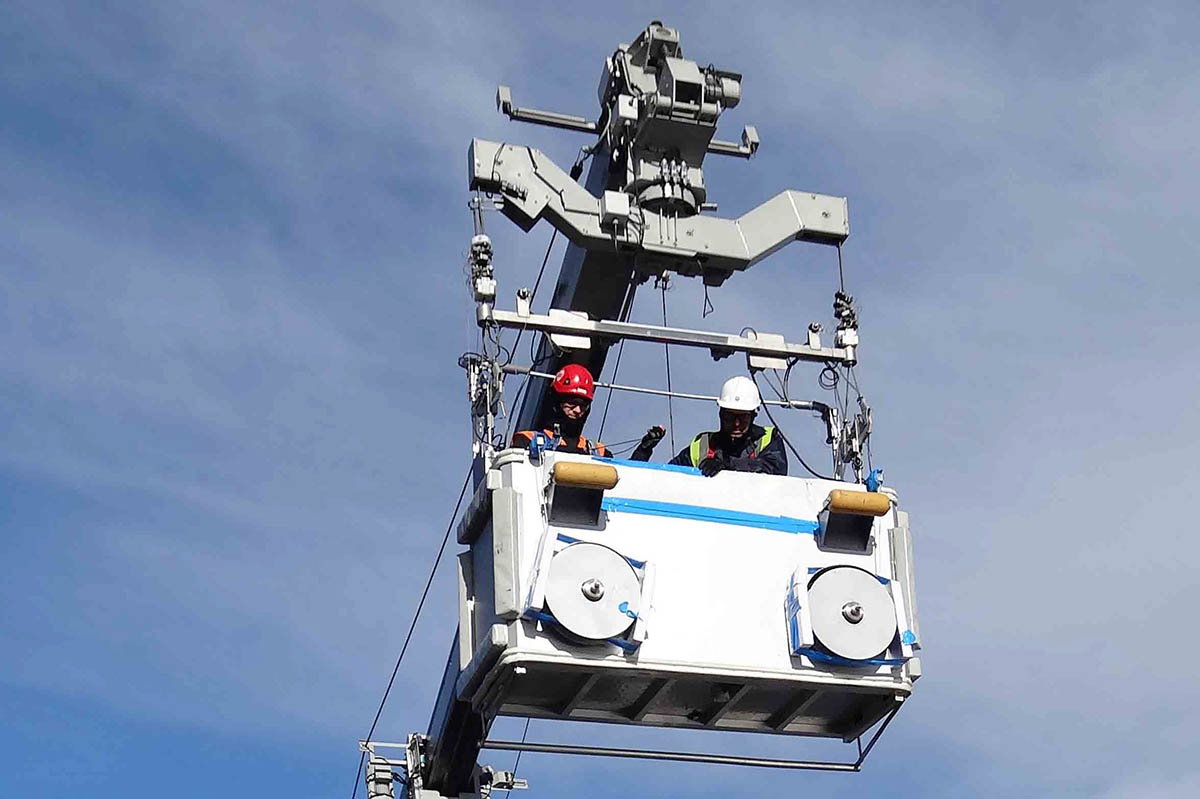

BMU ERGONOMICS

For BMU a minimum safety distance is requested between the facade and the cradle (not less than 50 cm). This gap forces operatives to lean out of the parapet in a definitively uncomfortable work position that exposes them to danger given that the cradle is subject to oscillations.

RA PRODUCTIVITY

Possibility of placing an almost unlimited number of operatives simultaneously working on the structure meet the Client’s requests concerning the duration of the operation.

BMU PRODUCTIVITY

The number of operatives is variable according to the dimension of the cradle, ranging from 1 to 6 units (In the COD case probably 2 operatives). The duration of cleaning depends on the number of BMUs installed on the building and the surface size. In the case of large areas, the time of the operations increases.

RA VERSATILITY

Possibility to reach any area of the building even in the case of complex shapes (curved faces, etc.) and narrow spaces.

BMU VERSATILITY

Areas with complex shapes are very difficult to clean (e.g. curved faces, vertical or horizontal, inclined or overhanging facades, corners, narrow spaces, etc). These areas often remain not served, or if a custom solution is adopted, it is generally very costly.

RA LABOUR FORCE

The daily production reaches 80 m²/h per operative. It is variable with the complexity of the facad but faster than a BMU.

BMU LABOUR FOURCE

The daily production is generally low around 30 m²/h per operative, given that BMU’s movement is quite slow. The distance from the facade is not optimal (at least 50 cm). It decreases strongly as the complexity of the facade increases.

RA SAFETY

The safety factor (intended as the ratio between the maximum design load and the real one) is very high (min = 12). This depends on the great redundancy of the bearing capacity of each component of the anchorage-line on its configuration.

BMU SAFETY

The safety coefficient (intended as the ratio between the maximum design load and the real one) is definitely lower (generally around 2.5)

RA FOOTPRINT

There is no need for dedicated spaces for housing the devices. These are very small, and they exploit specific openings on the facade (the access point for operatives is the roof).

BMU FOOTPRINT

The installation requires dedicated spaces for housing the machine in the rest position.

RA AESTHETIC IMPACT

The system has very little aesthetic impact as all the anchorages are very small and the accessories devices are removed after operations.

BMU AESTHETIC IMPACT

The aesthetic impact is relevant.

RA WIND SENSITIVENESS

Rope access is LESS wind-sensitive. A human body does not have large surfaces and is not subject to sail-effect. The main force is gravity and the operative does not swing if subject to wind.

BMU WIND SENSITIVENESS

Cradles are VERY wind-sensitive. As a countermeasure, special devices are adopted for preventing oscillations and this affects the optimal planning of the operations on not-windy days. Oscillations expose operatives to severe risks and the facade to possible damages.

RA TRAINING OF PERSONNEL

Rope access operators are highly trained and their formation is mandatory. Operatives also have specific training for rescue maneuvers. E.g. if a BMU breaks down at a level unreachable by firefighters’ ladders, operatives inside the BMU must be rescued by rope access.

BMU TRAINING OF PERSONNEL

The personnel has only “generic” skills. Operatives are trained to use PPE category 3 (for prevention from death risk) but have no specific training for rescue maneuvers. BMU’s producer is generally deputed to train personnel for the operation of the machine.

BMU FACTS

No reliable fonts of data.

BMUs are “machines” and as complex systems their failure possibility (including fatalities) is:

- Directly related to their complexity

- Inversely related to the frequency and quality of the check and maintenance procedures during the lifetime

The most frequent causes of failures and accidents are:

1. mechanical problems,

2. structural problems,

3. human factor

THE CAPITAL AND RUNNING COSTS

The main differences in direct and indirect costs

- Rope-access has lower capital cost by 30% to 60% on average vs BMU

- Lower running cost: while abseilers due to extra training and professional capacity do cost on average 20% more than BMU operators, the speed on facade, due to better positioning, is minimum 4 to 1.

- Trickle down effect #1: lighter roof structures and also foundations due to lightness of system

- Trickle down effect #2: lighter curtain wall system due to lower impact

- Trickle down effect #3: freeing practically all roof space which is most valuable real-estate asset

WHEN AN ACCIDENT OCCURS: ABSEILERS vs BMU

In case the cleaner worker anchors to the platform and the cable is failed causing the working platform to inclination enormously to one side or fall to the ground, the operator would be left hanging by the damaged BMU platform or may fall to the ground within it. In the event of an accident, workers must be rescued by firefighters or rope access operators and it can take hours.

When an accident occurs, BMUs are as safe as it is commonly perceived. There is a lot to do yet to enhance their safety.

On the other side abseilers in case of an accident are already prepared (their rescue procedure is defined in advance), skilled, know the building, have an anchor system ready to be used and are already there beside the injured person. The rescue is easy and fast. Rescued within 15 minutes.